Tags

07:10.

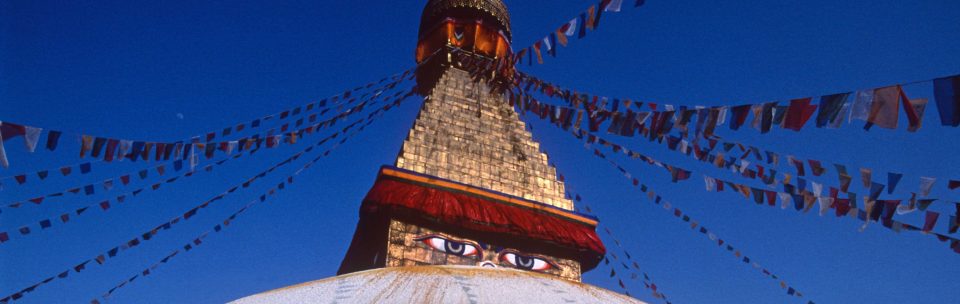

I reaisted the temptation to stay up and play with the Lego in my room (see yesterday’s blog) and had a good night’s sleep instead. The hotel’s very quiet and the curtains thick so I wasn’t disturbed. Now I’m making the most of the day with an early start. Here’s the view from the 16th floor restaurant where I’m enjoying breakfast. As you can see, it’s dull and overcast here. The view’s not bad tho!

Having had my caffeine fix I’ve time for a little wander before the bus picks us all up from the hotel.

08:25.

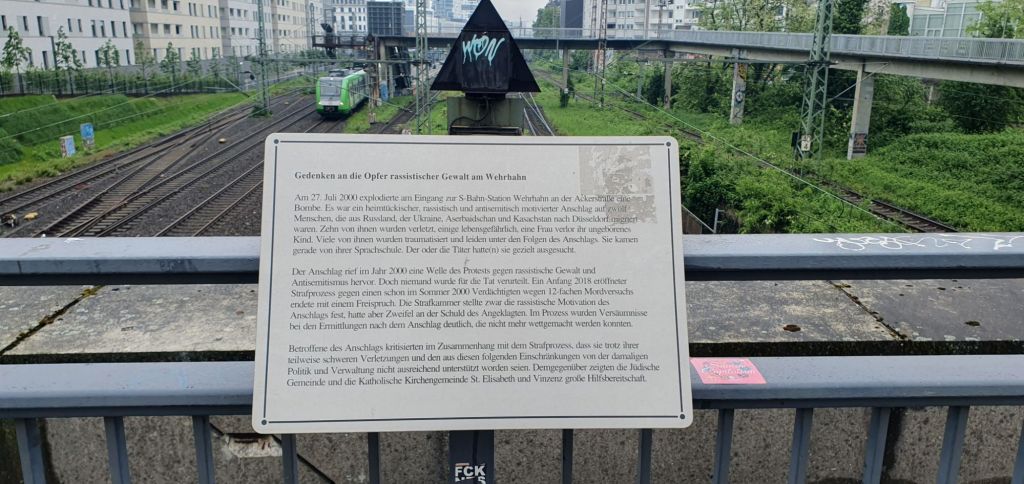

My stroll took me around the area you see in the picture above. A network of abandoned rail underpasses that lead to the area where I’m staying lead me to the concusion that my hotel and all the adjacent new buildings surrounding it are built on the site of an old railway yard. I’ll add some camera pictures later. I also came across this bit of history.

Right now I’m waiting in the rather eclectic hotel lobby…

09:55.

Our bus trio has taken us to Dortmund, where the weather’s far better. I find the difference in architecture interesting. Dortmund seems to have a real mix of old and new – and great pride in its football team! Their banner can be found all over the city. We’ve stopped outside the Hauptbahnhof to pick up more of the group. Across the road from the staion is the football club fanshop.

11:10.

We’re off! Today’s event is being held in one of the most modern train depots in Germay whic was built by Siemens for the new Rhine-Ruhr Express (RRX) fleet – and others…

17:00 (German time).

An interesting day.The Dortmund chapter’s now over and the whole crew (Journo’s and Siemens staff) are being bussed back to Düsseldorf before this evening’s group meal. I’ve lots to blog about later, such as the 150 million euro Siemens are making in the Dortmund depot, building a new 400m long building to service ICE trains. After the lunch we were given guided tours of the existing facility which dates from the introduction of the RRX Desiro’s in 2018. The depot building is far more solid than the UK style ‘tin shed’ construction. It’s also fully digital. There’s no paperwork here. The site also has its own 3D printer (one of 40 used by Siemens) which can print otherwise obsolete parts for trains. Despite the modern depot, automation and work practices there were a couple of surprises. One was the underfloor wheel lathe. It’s a single-axle machine supplied by Spanish company TALGO rather than German manufacturers. Apparently, wheel lathes are less common in Germany than they are in the UK, but then DB doesn’t have quite the same problem with wheel-flats caused by leaf fall. The other was the absence of a bogie drop. Instead, one road is equipped with jacks which can lift an entire train.

18:40.

We’re back at the hotel and enjoying a short break and chance to freshen up before the meal, so I’ve taken the time to download a few camera pictures. More will follow later.

19:45.

Time for a beer on the 17th floor restaurant and chance to admire the view before dinner.

I’ve a small favour to ask…

If you enjoy reading this or any of the other blogs I’ve written, please click on an advert or two. You don’t have to buy anything you don’t want to of course – although if you did find something that tickled your fancy that would be fab! – but the revenue from them helps me to cover some of the cost of maintaining this site (which isn’t cheap and comes out of my own pocket). Remember, 99% of the pictures used in my blogs can be purchased as prints from my other website – https://paulbigland.zenfolio.com/

Or – you can now buy me a coffee! https://ko-fi.com/paulbigland68312